I-70 Truck Automation Corridor

EASE has partnered with both public and private entities to implement diverse automation technologies, including platooning, along the 166-mile I-70 Truck Automation Corridor spanning from Columbus, OH to Indianapolis, IN.

IN THE NEWS

A CATALYST FOR CHANGE

About the Project

EASE is the host fleet partner of the I-70 project, working with DriveOhio, the Ohio Department of Transportation (ODOT), the Indiana Department of Transportation (INDOT), and Kratos Defense and Security Solutions.

This project examines the functionality of platooning technology, where trucks are electronically linked and use automated driving systems to proceed as a coordinated group. These trucks are effortlessly integrated into EASE’s existing freight transportation operations, enabling the movement of goods throughout Ohio and Indiana while also collecting relevant project data.

The conclusions from the audits and the application of automation technologies will be reported to the U.S. Department of Transportation (USDOT). Such information will be instrumental in shaping national guidelines and methodologies for enhancing truck automation and the formulation of design criteria for highways equipped for autonomous vehicles.

Kratos Technology: Built for Defense, Adapted for Business

With the Ohio Rural Automated Driving Systems project underway and EASE serving as the host fleet, Kratos Defense initiated discussions to explore future partnership opportunities. This led to a collaboration between EASE and Kratos to support the I-70 Technology Automation Corridor (TAC) program, which required advanced automated platooning capabilities making Kratos the ideal partner for the initiative.

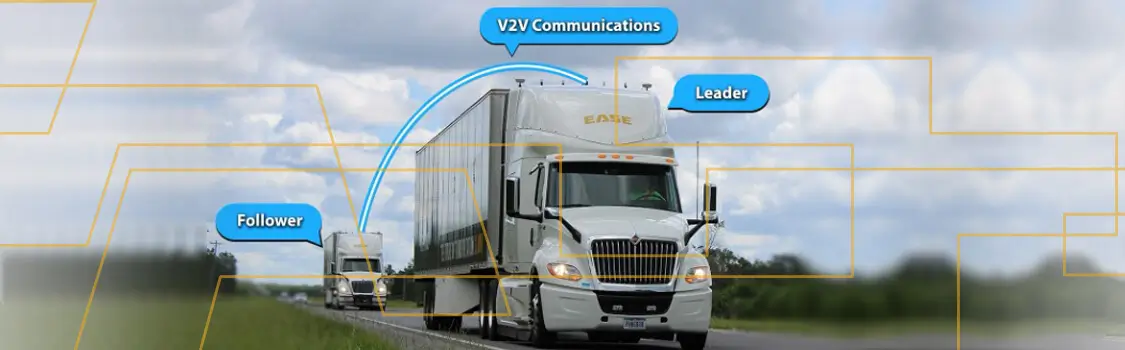

To support the I-70 TAC program, Kratos integrated its “Leader Follower” platooning system, originally developed for the Department of Defense to reduce the number of warfighters needed to support dangerous resupply and route clearance missions. The first adaption of the system was deployed with Department of Transportation (DOT) agencies across the United States for increasing Work Zone safety. These newly automated vehicles eliminated the need for humans to drive mobile crash barriers used to protect workers and equipment in mobile maintenance operations nationwide. Continuing to evolve the technology for a broader scope of commercial applications, Kratos then integrated systems on Class 8 tractor/trailers to address driver shortage impacts to business continuity. These automated platooning systems are currently deployed in the Agriculture, Renewable Energy, Forestry, and Logistics industries in 24/7 short-haul routes. The Kratos auto platooning technology is a “bolt-on” vehicle agnostic system that retrofits automation onto existing fleet vehicles. Once retrofit, the newly automated trucks enable customers to maintain haul capacities, despite driver shortages, by pairing each human-driven truck with an automated follower.

The collaboration between EASE and Kratos represents a dynamic partnership dedicated to advancing innovation in transportation.

Kratos brings EASE several distinct advantages:

- Field-Proven: Kratos offers real system solutions deployed across the U.S.

- Leader Follower Platooning: One human-driven Leader and one automated Follower (with a safety driver in the cab at all times).

- Retrofit Vehicle Agnostic Solution: A cost-effective solution for utilizing the existing fleet as an alternative to purchasing brand-new, purpose-built robotic trucks.

- Positive Public Perception: Maintains driver jobs and maintains a human-in-the-loop operator for increased safety.

- Driver and Driverless Modes: Fleet vehicles can be operated in automated or manual modes for greater deployment flexibility. In this deployment, we will not be testing driverless mode, although the technology is capable of doing so.

- Deployment: Operational in Day, Night, Twilight, harsh weather environments, and requires zero modification to roadway infrastructure.

What is Truck Platooning?

The initial deployment will feature two trucks operated by EASE, leveraging Kratos’ advanced platooning technology. This system connects multiple vehicles through vehicle-to-vehicle communication, allowing the lead driver to control speed and direction while the trailing vehicle precisely replicates these movements.

Automation vs. Human Reflexes: Who Stops Faster and Safer?

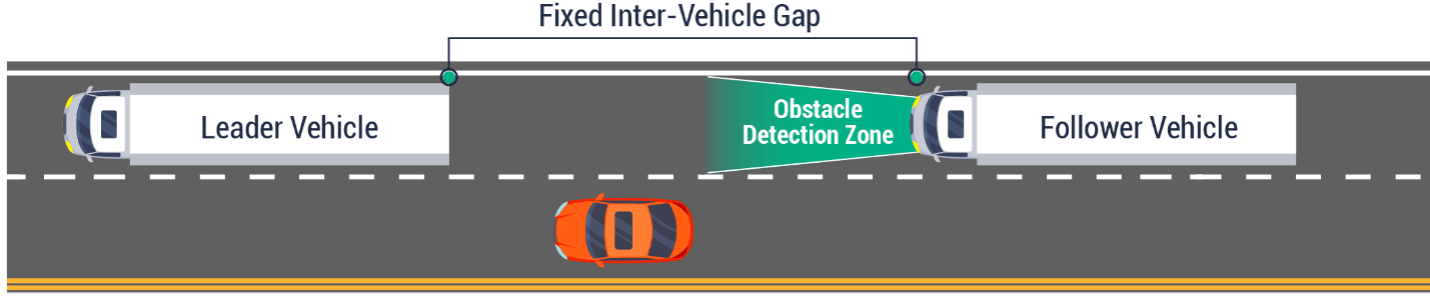

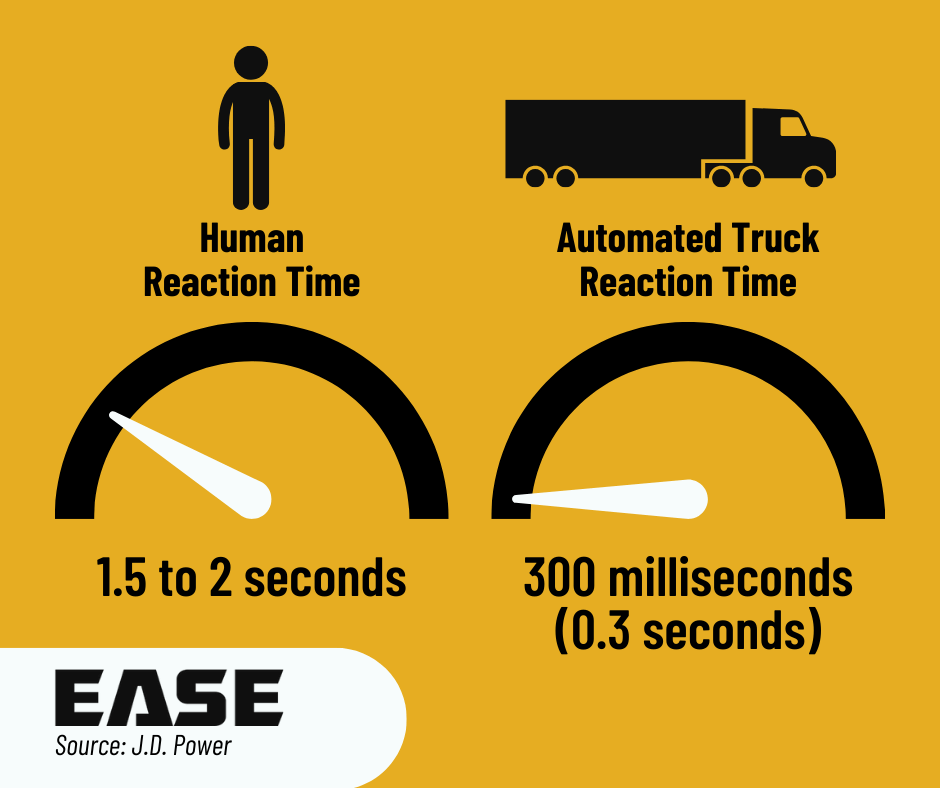

On average, stopping a vehicle takes approximately 6.5 seconds, factoring in reaction time, thinking time, braking time, and total stopping distance. A human driver typically requires 1.5 to 2 seconds to react, plus an additional 2.5 seconds to fully apply the brakes. At highway speeds of 70-75 MPH, a truck may need up to 60 yards (180 feet) to come to a complete stop—the length of half a football field.

In contrast, the Kratos platooning system reacts in just 300 milliseconds (0.3 seconds), dramatically reducing response time.

By minimizing human reaction delays, platooning enables trucks to travel more closely together, enhancing both efficiency and safety on the road.

Purple Lights Mean Platooning

These trucks have purple lights to signal their operation mode to highway patrol officers. This visual cue is key to safe road interactions. We’ve partnered with Ohio and Indiana State Highway Patrol to integrate our platooning tech seamlessly on highways. Regular communication and training ensure patrol officers understand the system and its benefits. By working together, we can ensure safe and efficient operations, benefiting everyone on the road.

Testing Varying Weather Conditions and State Laws

Automated commercial vehicles are now traveling millions of miles each year, mostly in the southwestern United States. Currently, they are tested where warm and predictable weather is common. However, expanding this technology requires testing it in more diverse settings.

Ohio and Indiana experience all four seasons and are ideal examples of weather conditions that might be encountered throughout the U.S., from the Northwest to the Midwest to the East Coast.

The goal is to investigate how these technologies perform in varying conditions—including changing weather, diverse road scenarios, and different state automation regulations—and their impact on trucking fleets that use these technologies.

?

?